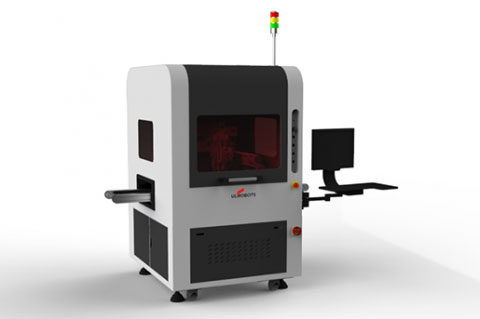

Product overview

On-line constant temperature laser solder machine is composed of X-Y-Z, wire feeding multi-axis spatial combination control, with the conveyor belt of the production line, infrared real-time temperature feedback system, CCD coaxial positioning system and semiconductor laser.The self-developed constant temperature laser soldering software can process the processing parameters in layers for different solder joints and different heights at one time. At the same time, it can monitor the completion of the operation in real time during the welding process.PID on-line temperature control feedback system, can control constant temperature welding, welding yield and precision.This product is suitable for assembly line production, can be very good to complete the joint of the next process, improve the automation degree of production line.

Product features

1. The equipment is equipped with online conveyor belt, front and rear ends can be connected to the production line assembly line, which can realize the automation of product feeding and discharging.

2.PC control, visual operation.High definition CCD camera, optional Mark +DXFGEBER pattern or template matching mode, automatic positioning, to meet the requirements of high precision components automatic or online processing, reduce manual intervention.

3.X-Y-Z axis and wire feeding shaft multi-axis linkage, for different solder joints, different heights of solder joints to achieve a processing.

4. Temperature control model with core technology, and adopt high-precision infrared temperature detector for real-time temperature feedback and control.

5. Non-contact welding, no mechanical stress damage, fast heating speed, small heat affected zone.

6. Laser, CCD, temperature measurement and indicator light are coaxial at four points, which solves the problem of multi-optical path overlap in the industry and reduces complex debugging.

7. Independently developed constant temperature laser soldering software, to realize the call and processing of different parameters, convenient for customers.

8. Full modular design of optical system, motion unit and control system improves system stability and maintainability

Applicable fields

PTH (hole direct insert components), PGAs (pin grid type electronic products), RFI field, connectors, hybrid reassembly components, strange shape components, etc.

| The input power | AC220V/50HZ |

| laser | Semiconductor laser |

| Laser power | 50W, 80W, 100W (optional) |

| Optical fiber core diameter | 200um, 400um, 600um (optional) |

| Focus on the smallest spot | 0. 18mm |

| Positioning way | CCD coaxial positioning |

| The scope of work | X - Y - Z - R: 100 *100 * 100 mm * 360 ° |

| The CCD view | 12.8 * 9 mm |

| The control mode | PC control, temperature feedback |

| Tin wire diameter | 0.3- 0.8 mm |

| Cooling way | Wind cooling |

| Size | 1300*1000* 1850mm |

Rotary multi - station automati

Rotary multi - station automati ULiTOBOTS four axis double slid

ULiTOBOTS four axis double slid Six axis manipulator line autom

Six axis manipulator line autom Single position precision const

Single position precision const